A Type Layer Chicken Cage System

Material: International Q235 steel

Anti-corrosion Treatment Process: Hot-dip Galvanized, Aluminum-Zinc Alloy

Lifespan: 15-20 Years

Ties: 3-4 Ties

Product Introduction

Product name: A type layer battery cage system

Material: International Q235 steel

Anti-corrosion Treatment Process: Hot-dip Galvanized, Aluminum-Zinc Alloy

Lifespan: 15-20 Years

Ties: 3-4 Ties

Capacity: 90-160 Layers

The A Type Layer Chicken Cage System has emerged as a game-changer in the poultry industry, offering a structured and efficient approach to egg production.

Specifications of A type layer chicken cage system

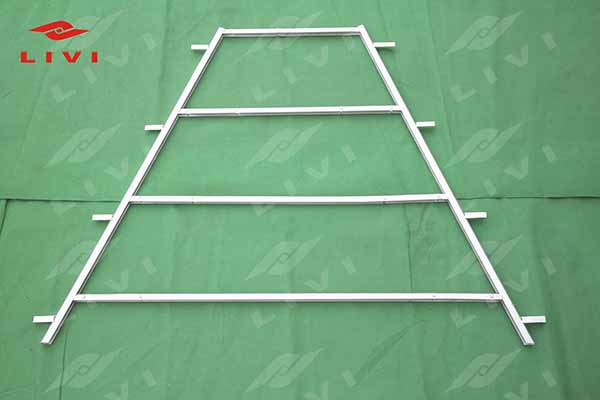

Solid construction

Hierarchical design

High quality metal material

Grid design

chicken drinking line

Dimensions: Tailored to accommodate varying flock sizes, offering flexibility for both small-scale and large-scale operations.

Spacing: Designed with precise spacing to ensure optimal ventilation and prevent overcrowding, promoting healthier bird growth.

Accessibility: Features easy-to-access sections for efficient egg collection, feeding, and maintenance.

| A-type Layer Chicken Battery Cage Specification | ||||

| Type | Model | Birds Qty/Door | Birds Qty/Unit | Specification |

| A-Type | 3-Tier 4-Door | 4 pcs | 96 pcs | 1950mm*350mm*380mm |

| 3-Tier 5-Door | 3 pcs | 90 pcs | 1950mm*350mm*380mm | |

| 4-Tier 4-Door | 4 pcs | 128 pcs | 1950mm*350mm*380mm | |

| 4-Tier 5-Door | 3 pcs | 120 pcs | 1950mm*350mm*380mm | |

| 4-Tier 5-Door | 4 pcs | 160 pcs | 1950mm*450mm*410mm | |

Complete Raising System of A type layer battery cage

A comprehensive poultry equipment setup is essential for optimizing the efficiency and productivity of a poultry farm. Here’s a breakdown of the integral components.

Egg Collection Equipment

Purpose: Facilitates the efficient and hygienic collection of eggs.

Features: Includes automated conveyor systems, roll-out nest boxes, and sorting mechanisms to streamline egg collection and minimize breakage.

Chicken Feeding Equipment

Purpose: Ensures consistent and timely feeding of poultry.

Features: Incorporates automated feeders, silos, and distribution systems tailored to the specific nutritional needs of chickens at various growth stages.

Chicken Manure Removal Equipment

Purpose: Facilitates the efficient removal and management of poultry waste.

Features: Includes conveyor belts, scraper systems, and composting solutions to maintain cleanliness and hygiene within the poultry environment.

Environmental Control Equipment

Purpose: Maintains optimal environmental conditions within the poultry house.

Features: Incorporates ventilation systems, heating solutions, and humidity control mechanisms to create a comfortable and conducive environment for poultry growth and well-being.

Livi Machinery’s Advantages

Expertise: Backed by years of industry experience, we understand the intricacies of poultry farming and continuously innovate to meet evolving needs.

Quality Assurance: Committed to excellence, our Layer Battery Cage Systems undergo rigorous quality checks, ensuring reliability and performance.

Customer Support: Our dedicated team provides comprehensive support, from installation guidance to ongoing maintenance, ensuring a seamless experience for our clients.

Chicken Raising Equipment For Sale

Certificate: ISO9001, ISO14001, OHSAS18001, CE, SONCAP, PVOC

Production Lead Time: Depending on the order quantity. Normally about 10 days for 20ft container, 15 days for a 40ft container.

Supply Ability: 10000 Set/Month

Packing Method: Normal export packing. 20ft / 40ft container.

Payment Method: T/T, L/C at sight

Trading Method: EXW, FOB, CFR, CIF

Livi Machinery’s Service

- High quality Chicken cage

- Complete chicken raising equipment

- 365-Day First-Class Service

- Get a Free Quote – Design Within 24 Hours

- 15-45 Days Production

- 60-Day Installation

- Customizable service

- Free chicken house design

In conclusion, the A Type Layer Battery Cage System stands as a testament to innovation in poultry farming, offering a comprehensive solution tailored for efficiency, productivity, and sustainability. With its array of features and our unwavering commitment to quality and support, it remains a preferred choice for poultry farmers worldwide.