Designing a Large Scale Chicken House with 20,000 Capacity: A Comprehensive Guide

As the poultry farming industry continues to grow, the demand for large-scale chicken houses with high capacities has become increasingly significant. In this article, we will discuss the key factors to consider when designing a 20,000 capacity chicken house, including the necessary poultry farming equipment and automated chicken cages.

Key Components of a Large Scale Chicken House

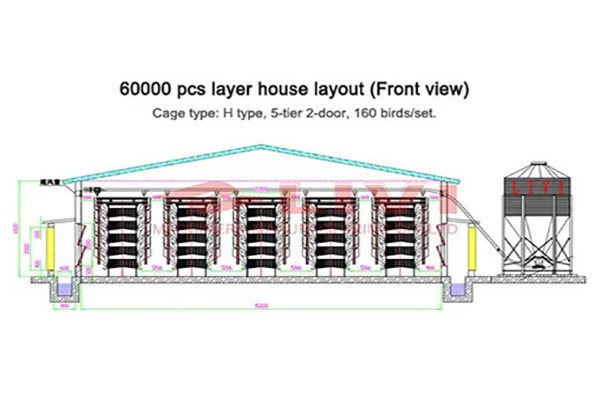

- Structural Design: A robust and durable structure is essential for housing a large number of chickens. The design should incorporate ventilation, insulation, and temperature control systems to ensure the well-being of the birds.

- Ventilation System: Proper air circulation is crucial in maintaining a healthy environment for the chickens. A well-designed ventilation system will help regulate temperature and humidity levels, reducing the risk of disease.

- Feeding and Watering Systems: Efficient feeding and watering systems are essential for the growth and productivity of the chickens. Automated systems can reduce labor costs and ensure that the chickens receive the necessary nutrients and hydration.

- Automated Chicken Cages: Automated chicken cages provide a controlled environment for the chickens, reducing the risk of disease and improving productivity. These cages can be programmed to adjust feeding, lighting, and temperature settings.

Benefits of a Large Scale Chicken House with 20,000 Capacity

Building a large-scale chicken house with a 20,000 capacity offers several benefits:

- Increased Production: A larger capacity allows for increased production, which can lead to higher revenue for the farm.

- Reduced Labor Costs: Automated systems can reduce the need for manual labor, saving time and money.

- Improved Health and Productivity: A controlled environment with proper ventilation, feeding, and watering systems can lead to healthier chickens and higher productivity.

Case Study: Large Scale Chicken House with 20,000 Capacity

XYZ Chicken Farm, located in the United States, recently constructed a large-scale chicken house with a 20,000 capacity. The farm invested in high-quality poultry farming equipment and automated chicken cages to ensure optimal performance. As a result, the farm experienced a 30% increase in production and a 20% decrease in labor costs.

Conclusion

Designing a large-scale chicken house with a 20,000 capacity requires careful planning and consideration of the necessary poultry farming equipment and automated chicken cages. By investing in the right systems, poultry farmers can improve production, reduce costs, and ensure the health and well-being of their chickens. If you are considering building a large-scale chicken house, contact LIVI Mechanical for a free poultry farming design and equipment quote.