Low Cost Poultry Automation for 10,000 Layers in Nigeria: Cost-Effective Solutions

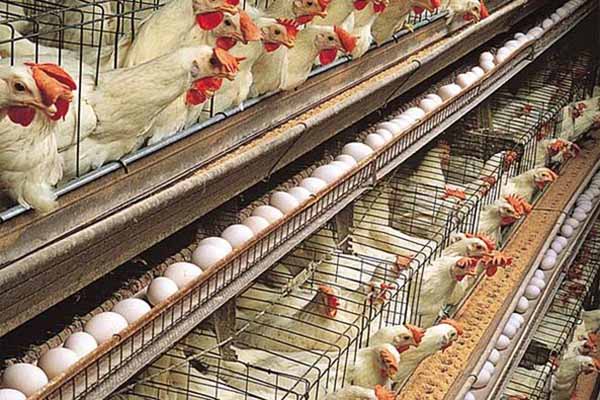

As the poultry industry in Nigeria continues to grow, many farmers and investors are seeking cost-effective ways to automate their operations. With the aim of increasing productivity and reducing labor costs, implementing an automation system for a 10,000-layer poultry farm can be a game-changer. In this article, we’ll explore the benefits of low-cost poultry automation and provide a comprehensive guide to achieving this goal.

Understanding the Need for Automation

With a rapidly expanding poultry industry, Nigerian farmers are under immense pressure to increase production while keeping costs down. Automation can address these challenges by:

- Decreasing labor costs

- Enhancing biosecurity

- Improving feed conversion rates

- Boosting egg production

Key Components of Low Cost Poultry Automation

When considering an automation system for a 10,000-layer poultry farm, it’s essential to focus on the following key components:

- Feeding Systems: Automated feeding systems can ensure consistent feed delivery, reducing waste and improving growth rates.

- Watering Systems: Automated watering systems provide clean water to the birds at all times, crucial for their health and productivity.

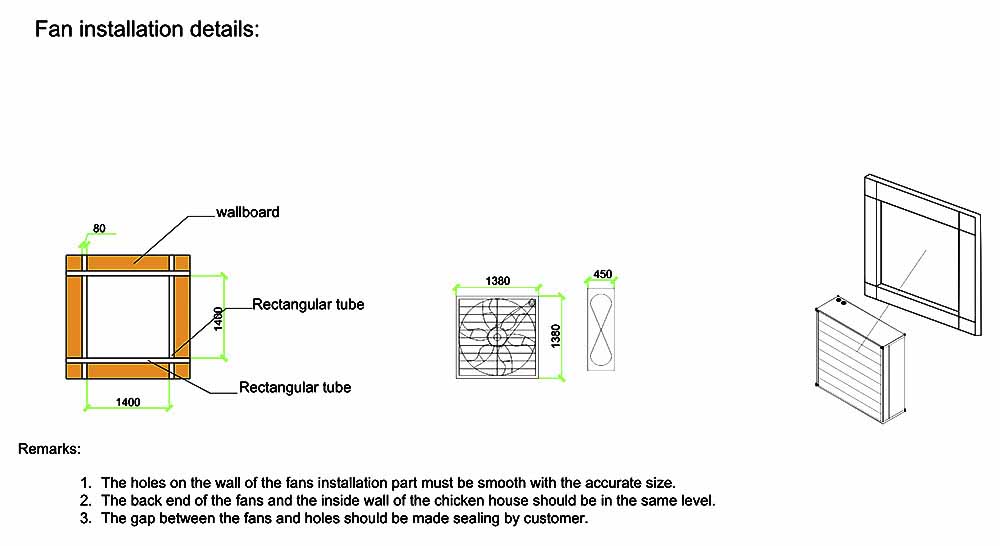

- Environmental Control: Climate control systems maintain optimal temperature and humidity levels, reducing the risk of disease outbreaks.

- Monitoring and Data Collection: Sensors and cameras can track bird behavior and health, allowing for early intervention and improved management.

Cost-Effective Automation Solutions for 10,000 Layer s

s

Implementing an automation system for a 10,000-layer poultry farm in Nigeria doesn’t have to be expensive. Here are some budget-friendly solutions:

- Manual Feeding Systems: Use manual feeders for smaller batches and supplement with automated systems for larger ones.

- Gravity-Driven Watering Systems: Simple and cost-effective, gravity-driven systems are suitable for small to medium-sized farms.

- Smart Sensors: Invest in low-cost sensors to monitor key parameters like temperature, humidity, and feed consumption.

- Mobile Apps and Drones: Utilize technology like mobile apps and drones for remote monitoring and management.

Case Study: Success with Low-Cost Automation

One Nigerian poultry farm successfully implemented a low-cost automation system, resulting in the following benefits:

- Reduced labor costs by 30%

- Increased egg production by 20%

- Significant improvement in biosecurity

Conclusion

Low-cost poultry automation is a viable option for Nigerian farmers looking to enhance their operations.  By focusing on essential components and budget-friendly solutions, a 10,000-layer poultry farm can achieve significant improvements in productivity and profitability. For more information on custom automation solutions and free design quotes, feel free to leave a comment below or contact us directly.

By focusing on essential components and budget-friendly solutions, a 10,000-layer poultry farm can achieve significant improvements in productivity and profitability. For more information on custom automation solutions and free design quotes, feel free to leave a comment below or contact us directly.