Optimizing Automatic Egg Production in Kenya with Advanced Caging Systems

As the poultry industry in Kenya continues to grow, the demand for efficient and automated egg production systems has surged. Implementing an automatic egg production cage system can significantly enhance productivity and reduce labor costs. In this article, we will explore the benefits of using automatic egg production cages in Kenya and provide insights into the latest technologies available.

Benefits of Automatic Egg Production Cages

- Increased Productivity: Automatic egg production cages are designed to maximize egg yield, with some systems able to produce up to 300 eggs per hen per year.

- Reduced Labor Costs: Automation minimizes the need for manual labor, allowing farmers to focus on other aspects of their business.

- Improved Egg Quality: Cages provide a controlled environment that reduces the risk of contamination and ensures consistent egg quality.

- Healthier Hens: Automatic feeding and watering systems ensure that hens receive balanced nutrition, leading to healthier birds and fewer diseases.

Market Trends in Kenya

According to a recent report by the Kenya Poultry Development Association, the Kenyan poultry industry is expected to grow at a compound annual growth rate (CAGR) of 5.5% between 2020 and 2025. This growth is attributed to factors such as increasing urbanization, rising per capita income, and a growing demand for eggs and poultry meat.

As the industry expands, the need for advanced egg production systems becomes more critical. Automatic egg production cages are becoming a popular choice among Kenyan farmers due to their efficiency and cost-effectiveness.

Choosing the Right Automatic Egg Production Cage System

When selecting an automatic egg production cage system for your Kenyan farm, consider the following factors:

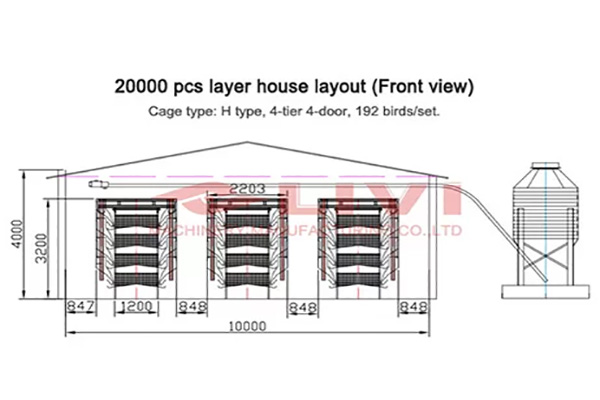

- Capacity: Choose a system that can accommodate the number of hens you plan to raise.

- Automated Features: Look for systems with advanced automation features, such as automatic feeding, watering, and egg collection.

- Material Quality: Ensure that the cage material is durable and resistant to corrosion.

- After-Sales Support: Opt for a supplier that offers comprehensive after-sales support, including installation, maintenance, and technical assistance.

Case Study: Success with Automatic Egg Production Cages

One Kenyan farmer, Mr. Joseph Mwangi, implemented an automatic egg production cage system on his farm. After just one year, his farm’s egg production increased by 25%, and h is labor costs decreased by 40%. Mr. Mwan

is labor costs decreased by 40%. Mr. Mwan gi attributes his success to the advanced automation features and high-quality material of the cage system.

gi attributes his success to the advanced automation features and high-quality material of the cage system.

“The automatic egg production cage system has been a game-changer for my farm,” said Mr. Mwangi. “It has not only improved my productivity but also provided a healthier environment for my hens.”

Conclusion

As the poultry industry in Kenya continues to grow, investing in an automatic egg production cage system is a smart decision. With the right system, you can achieve higher productivity, lower labor costs, and improved egg quality. Contact us today to learn more about our LIVI mechanical automatic egg production cage systems and receive a free design plan and equipment quote.